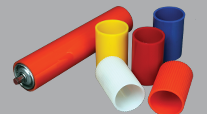

Plastic Extrusions

Plastic extrusions are used moment in all the major diligence that are present in our current days. We're facing the fastest meter of technological elaboration that has ever been recorded and it would appear that plastic accoutrements are then to help us in this evolutionary race.

We should first of all bandy the advantages of plastic. A material that isn't relatively natural it's used nearly in all diligence and has some great features and advantages for any operation. It's veritably light weight and can be fluently moulded into any shapes asked for any purpose. It's also veritably easy to produce therefore it'll also be veritably cheap to buy and use in your company's biographies. The stylish and worst property that plastic has is that's lasts a veritably long time.

This is why it's one of the main accoutrements used moment in all diligence; still, it isn't biodegradable and if left in nature will keep it's shape and parcels and won't be incorporated in to the soil. There are numerous species moment that can die because they've plastic beer holders crammed in their throats or over some of their branches therefore they come vulnerable to their normal bloodsuckers and are in great peril.

Plastic extrusions are used substantially in artificial areas and also present a number of advantages; still, the product process of plastic extrusions is veritably intriguing and for that respect I'll try to explain it to you compactly.

First of all a small blob or sphere of thermoplastic material is dropped in to the top opening of the plastic extrusion machine and gently drops on to a screw that revolves at 120 reels per nanosecond which in turn pushes the blob into the main barrel of the machine. After this first step is completed the thermoplastic material is hotted to the required temperatures to be moulded to the guests preferences and design schemes. The barrel of the machine can induce temperatures that vary between 320 degrees Fahrenheit and 570 degrees Fahrenheit. After this step is completed the material passes through a cleaning process to be relieved of any contaminations and also it's cooled so that it'll gain it's final form.

This is the description of the plastic extrusion process and I'm enough sure that now you know a bit further than you did 5 twinkles agone and you can explain this way to someone differently how extrusions are born.

Comments

Post a Comment